Machined engine components preserved for packaging, warehousing, and shipping on-demand.

Product delivered and readied for preservation.

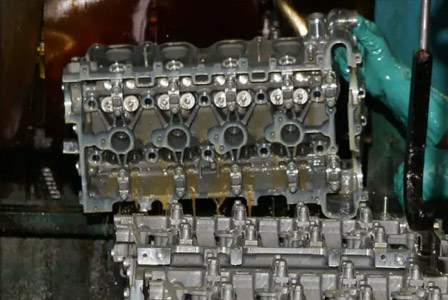

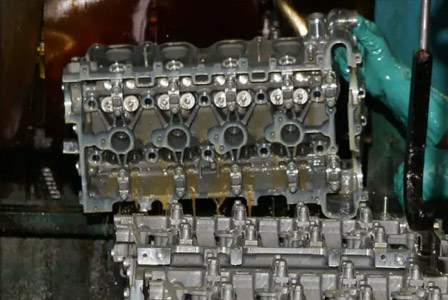

Product placed in-line and ready for contact preservation fluid.

Product zoom-view, after being dipped in preservation protection fluid.

Product after being dipped in preservation protection with excess being drained back into vat bath - now placed in-line for additional drainage and readied for coating inspection.

Product preservation step thoroughly examined and readied for packaging and shrink-wrap for storage and warehousing.

Preserved packaged product boxed, wrapped, warehoused, and read for on-demand shipping to automotive dealerships throughout the US and Internationally.

Send us details about a packaging project you need, and a member of our expert team will be in touch.